Written by: Abroo Murtaza

While enrolment rates and the educational institutes’ resources are acceptable in developed countries, developing countries are still working on such policies and practices. ISO Quality Management System should be favoured in the educational institutions to be used for improving their teaching practices for the purpose of standardization. This is especially true with the increased reliance of distance learning as even though institutions had worked on education dynamics, children who need to should be able to efficiently and effectively finish high school online diplomas and degrees in a similar manner to what they would achieve with in-person learning.

An ISO 9001 quality management system (QMS), that is based in educational organizations, should be considered an essential element concerning the involvement in academic institutions to improve their central management of the institutes. That includes the curriculum designing, its implementation, and its outcomes in the student’s achievements by providing the evidence on the entire educational cycle utilizing capacities, from the management, curriculum design, learning results, client’s internal and external satisfaction –teachers, students, and families- and its impact by external achievement measurements.

Improvements in Teaching and Learning standards

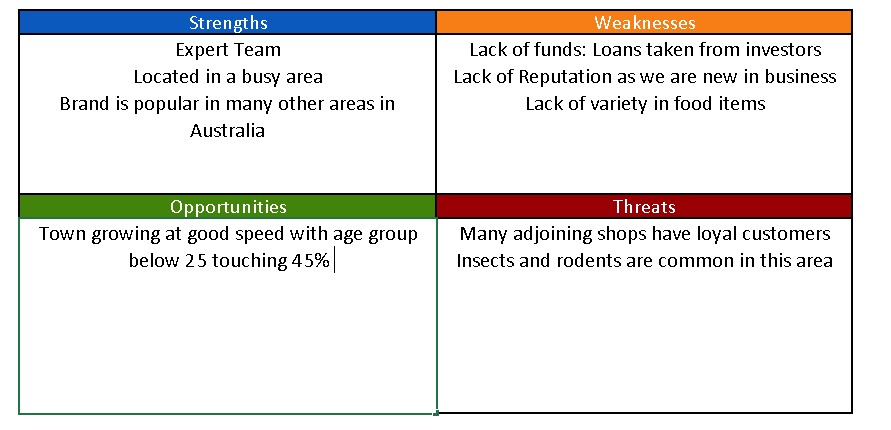

Adopting ISO 9001 in schools can help to improve the overall teaching and learning standards of institutions through standardizes and effective processes and management systems. It also helps in improving the processes and documentation by adopting the strategies of continuous improvement through learning and growth from mistakes. Not only this, but it can even help in fault preventions instead of correction the use of various tools to determine the organizations strengths, shortcomings, and ideally preventing anything from slipping through the cracks. The processes of various checks and balances throughout various processes allow organizations to be sure mistakes that are made are caught and corrected, among other things. ISO 9001 and an effective QMS can provide a very positive influence on the institution’s achievements by allowing teachers and employees more room for creativity in their teaching and increased focus on their students because less of their time is spent managing unstandardized approaches to their various administrative and process-based roles in their job.

Positive impacts on students learning and Teachers satisfaction

ISO 9001 can contribute a lot to improving the formative processes that positively affect the students’ learning and overall satisfaction in the institution. It allows for institutions to determine how each process affects another, and where and when shortcomings or faults can occur and how to ensure they do not. This allows your institution to focus on doing your job properly, with the assurance that the quality will not suffer. This will enhance the image of the institution as your “customers” (parents, students, stakeholders, investors, etc) can interact with your institution in a manner that feels cohesive, on-brand, organizations, and effective because you have a better systematization of managerial procedures. Even the vocational institutes use such standards for strategic focusing and a foundation for planning.

Proactive in showing benefits of quality

ISO 9001 Certification shows your institution is proactive and outwardly showing the benefits you hold over other institutes by upholding the notion of quality concepts and proving it by holding an accredited certification to stakeholders. Each QMS is unique to the organization because no two organizations hold the same set of procedures, policies, personnel, and property that make your institution tick. Obtaining certification to ISO 9001 is no small task, and often takes months to implement a QMS, and have it effective and ready for a certification audit. Those organizations who are certified should be proud and promote their accomplishment.

Find a Consultant to help implement your ISO 9001:2015 Quality Management System effectively.

Improves quality of education for workplaces

The extraordinary favour of ISO 9001 is its output that can be absorbed in any industries, including educational institutions. Adoption of a QMS has changed the learning setups of students who want more work performing arrangements or increased capacity of institutions with standardized approaches to various processes. With the added benefit of Continued Improvement, institutions can introduce different learning methods or new practical features for studies based on feedback that may provide benefits to students in their various industries. It has moved the mindsets of how quality management in educational institutions helps bring things systematic and documented.

Helps in teacher’s development

ISO 9001 can help teacher’s in their development as well. It supports in teaching-learning planning systems that include the learning resources, the realization of the teaching-learning process, the students’ assessment and feedback, and the evaluation of the general design, implementation, and results, providing evidence of the entire cycle utilizing measurements using different and specifics instruments, from the institutional organization, the curriculum design, the leaning process, their results, and impact.

Wrapping Up!

ISO 9001 has raised the quality standards of the educational institutes that have adopted it. It has provided such criteria that institute proper directions for growing and settling their work setups directionally and adequately. A QMS provides a unique and complete backbone to the educational institutions for designing their process-based approach to effectively running their institution to deliver quality education through well-made curriculums and documentations, adopting strategies and procedures for the efficient observable workings and ensuring continual improvements of their processes.

Author Bio:

Abroo Murtaza is one enthusiastic and passionate writer who loves to write about travelling based on the interest of exploring new places, reading about them, and then delivering the knowledge through her pen. Moreover, Abroo is also fond of writing about education, technology trends, gadgets like mobiles, cameras, etc. She thus strives to provide accurate information and knowledge in respective areas of interest and educate people on real terms.

In the aerospace industry, the National Aerospace and Defence Contractors Accreditation Programme (NADCAP) plays a major, and mandatory, role acting as an approval body of the process used and ensuring the product is correct.

In the aerospace industry, the National Aerospace and Defence Contractors Accreditation Programme (NADCAP) plays a major, and mandatory, role acting as an approval body of the process used and ensuring the product is correct.