SEUs – Significant energy users as defined by ISO 50001 – are the systems/equipment that consume a sizable quantum of total energy consumed and also offer a good number of energies saving opportunities and scope for energy performance improvement. Many organizations find it difficult How to identify significant Energy User? What are the criteria that could be applied to identify the SEUs? Can we duplicate the criteria applied in similar industries? Well, these confusions could be managed with application of the experience and knowledge gained within the organization on following

- Energy consumption profile (6-12 months)

- Nature energy intensive process/systems/equipment (running hours and capacity utilization)

- Level of technology (Age of equipment/technology upgradation)

- Maturity of other standards like ISO 9001, 14001

- Failure rates of equipment (mostly prime movers – motors)

- Type of energy use (Primary or Secondary, Renewable or conventional)

- Skill level of shop floor personnel/operators (Qualified or trained without qualification)

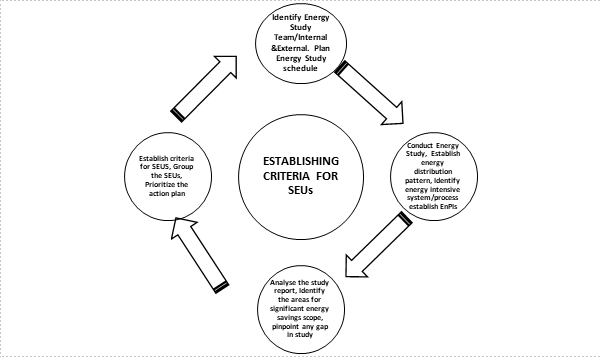

ISO 50001 facilitates the correct identification of such systems/equipment that needs continuous monitoring of relevant and static variables to maintain and improve energy performance. The complete process can be fit into PLAN-DO-CHECK-ACT cycle as shown in Fig. 1. These are the steps could help organization to establish robust methodology to identify SEUs.

Step-1

Conduct a detailed energy audit/energy use study. The scope must be limited to establish energy use patterns across the organization – not necessary to identify saving opportunities at this stage.

Step-2

Analyse the outcome of Step-1 and discuss with all stakeholders. Gather information on the practicality of implementing effective data collection relevant to energy performance improvement. Open the findings of Step-1 and discuss on the energy use pattern with operators and motivate them to contribute innovative ideas (remember the operators/shop floor are the best energy auditors!!). Generate a report of the following:

- Comments/opinions received from operators, managers and heads of departments and utility manager

- List all the equipment/process in the order of highest to lowest energy consumption and EnPs (Energy consumed/unit of output)

Step-3

Brainstorm with energy manager and department heads and list out the tasks on priority- which department/equipment needs top priority to improve energy performance.

Step-4

Fix the criteria for SEUs. For example, that equipment consumes xxxx % of total energy will be categorised as SEUs. The criteria should be acceptable and implementable by all interested parties. Re-assure the commitment of top management. Review and revise energy policy, objectives and Targets.

Step-5

Communicate to all interested parties with all necessary plans of action and support to measure and monitor all relevant and static factors of SEUs. Establish procedures, methodology and frequency of energy performance assessment. Scope of energy saving potential and economic benefits shall be established and implemented.

Step-6

Monitor and review on defined interval for effective implementation to reap the benefits. Repeat steps 1-5 on a regular interval (may be once in a year initially and then the frequency may be reduced).

ISO 50001 thus facilitates the organization in a systematic way to improve energy performance on a continuous mode and make the process sustainable.

*******

About the Author

Dr. Marudhappan Sambandam (IRCA, QCI-NBQP, CEA) based in India holds more than 30 years of experience in the Energy Conservation and Management domain and expertise in Energy Management System (ISO 5001-2018) LA/IA Training and implementation. His domain expertise is supported by 500+ energy audit projects across various industries and commercial buildings.

He is a Certified Energy Auditor by Bureau Of Energy Efficiency by Govt. of India and offers consultancy in energy audits. He is also a registered IRCA-UK and QCI-NBQP for Lead Auditor and Trainer for EnMS, ISO 50001. He is helping in Training and Auditing as per ISO 50001. He has trained more than 5000 participants in the area of Energy Audit and Energy Management System Audits from India and UAE. He can be reached @ +91 8523969321 / drmts1965@gmail.com

ISO Terms Explained

To the novice quality manager, ISO jargon can be extremely overwhelming. What is an NCR? What do you mean by OFI? Are we certified or accredited? But before you go and pull out your hair, let’s take a moment to go over some of the most frequently used terms and their definitions with regards to ISO and Management System Certification.